The 999 DRY combines automation, artificial intelligence, and real-time traceability, ensuring efficiency and quality at every stage of grain management. The equipment can be integrated into different stages of the storage process.

Loc Solution, the company responsible for the Motomco brand in Brazil and a reference in grain moisture meters, is launching the 999DRY, an innovative flow meter set to revolutionize control and traceability in grain management. The launch of the 999DRY reaffirms the company’s pioneering spirit, consolidating its position as a leader in grain storage technology.

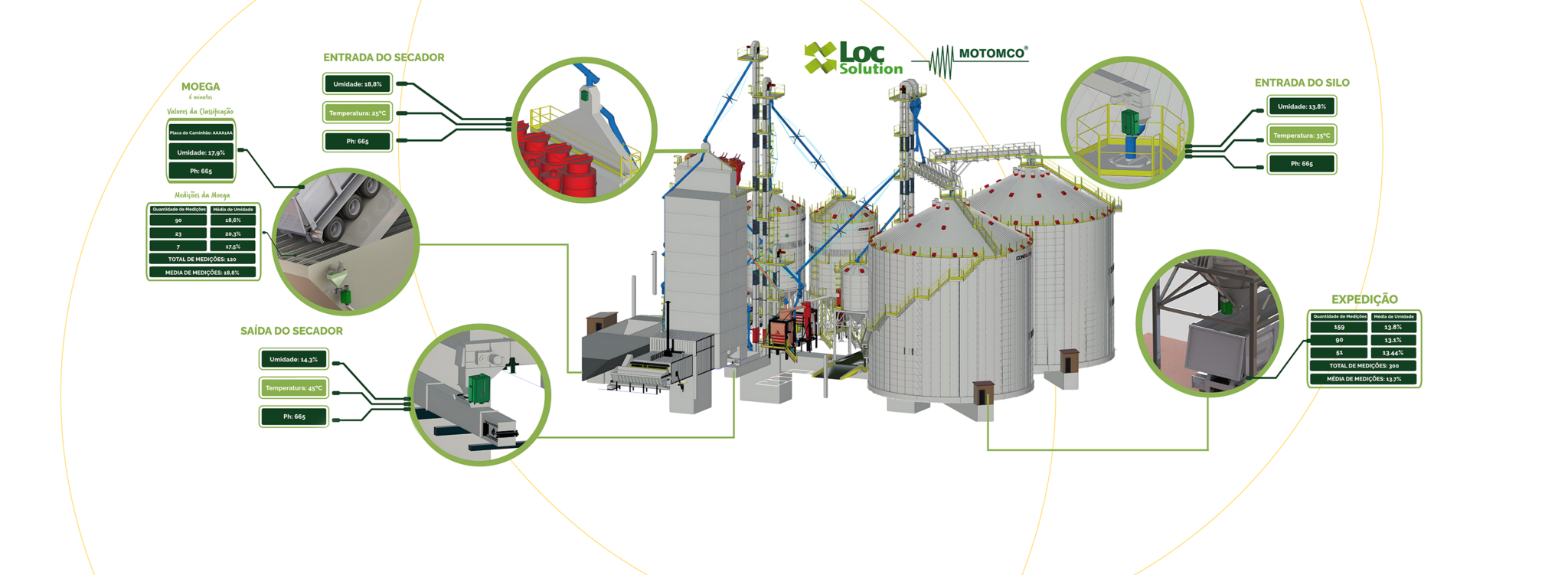

The equipment can be integrated into different stages of the storage process. “Originally designed to be installed in the dryer, during a reassessment of its functionality, we identified that it can also be used in other strategic points within the storage facility, such as in the receiving pit, at the silo entrance, and during load shipment (truck loading),” explains Fernanda Rodrigues, Relationship Manager at Loc Solution.

In addition, the equipment allows for monitoring the traceability of grains within the unit. “At the dryer’s inlet and outlet, for example, it records the moisture percentage, accurately indicating the levels at which the grain enters and exits, optimizing quality control,” she adds.

“The main differentiator of the equipment is its full automation. It automatically collects samples in a continuous flow of grains, meeting all process requirements,” details Fernanda.

With measurements taken every minute during the drying process, the 999DRY delivers real-time data, enabling fast and accurate decision-making. “It’s an advance in speed and precision, allowing measurements in places where this was previously not possible,” highlights Fernanda.

Traceability and Return on Investment

The 999DRY provides greater control over grain quality, speeding up the return on investment. Its traceability ensures efficiency in receiving and dispatching, positively impacting productivity and operational safety.

The dryer monitoring system significantly improves grain quality, precisely adjusting the drying process. This prevents both the storage of high-moisture grains, which hampers preservation, and excessive heat, which can cause dry matter loss and increase breakage. This balance ensures greater energy efficiency and process quality.

“With the support of Motomco sensors and real-time information management software, it is possible to significantly improve annual results in storage units,” says Fernanda.

Furthermore, Motomco’s SGU – Unit Management System complements the equipment, offering online data visualization, automated alerts, and decision-making support. “The solution reflects our commitment to transforming the grain sector with accessible and effective technologies,” Fernanda emphasizes. According to her, the equipment offers a robust, intelligent, and efficient solution for grain measurement and management, ensuring operational quality and precision.

Highlights of the 999DRY

With almost 30 years in the market and over 10 years dedicated to equipment rental, Loc Solution has devices operating in cooperatives, trading companies, warehouses, and farms across Brazil’s main producing regions.

Among the key features of the equipment, Fernanda highlights the following: automatic grain detection with an integrated camera and artificial intelligence system; fully automated operation without operator interference; standard calibration with INMETRO and USDA certifications; Ethernet connection and integration with the SGU system; real-time monitoring, minute by minute; ability to provide precise grain density, temperature, and moisture content readings.

The remote control integrated with continuous moisture monitoring allows for real-time adjustments in the drying process, ensuring precision, resource savings, and grain quality, all with the convenience of remote operation and enhanced operational safety.

Practical Applications of the 999DRY

- Receiving Pit: Monitors grain moisture and density with up to 400 samples per load, generating detailed classification reports.

- Dryer Inlet: Automates the drying process, adjusting in real-time based on grain moisture levels. This results in greater energy efficiency and uniform drying.

- Dryer Outlet: Monitors load release from the dryer in real time, with automatic alerts for moisture levels outside the set range.

- Silo Entrance: Evaluates moisture to aid decision-making, reduce human errors, cut aeration costs, and improve storage efficiency.

- Load Dispatching: Provides comprehensive reports on shipped loads, ensuring transparency and process monitoring.

About Loc Solution/Motomco – Loc Solution, headquartered in Curitiba, holds the Motomco brand of grain moisture meters. The company manufactures, sells, and rents the equipment, serving as a benchmark in various agricultural regions across Brazil. Originally from Canada, Motomco is the national leader in the grain moisture meter segment. More information can be found at motomco.com.br.